Application of Core Process Mapping: an example

Introduction

This article explains core process mapping that directly contribute to the production of Tasty-Beans brand of canned beans owned by Tasty-Beans Co. by to be delivered to Sainsbury’s Plc distribution centres, one of the largest supermarket chains in UK. Moreover, the paper contains in-depth illustration of lower-level mapping that focuses on packaging element of core business processes. Core business processes of Tasty-Beans Co. in general, and packaging element are explained in this paper with the application of ‘Four V’s’ and IGOE frameworks.

Tasty-Beans Operations Core Process Mapping

Business process can be defined as “well-understood interplay of activities that targets a certain business objective” (Draheim, 2010, p.75). Accordingly, for the case of Tasty-Beans, business process relates to the process of manufacturing and selling canned beans for the purposes of profit maximisation.

Business processes can be divided into two categories: core and support. Core processes related to the production of products and services in direct manner, and they include operations, inbound and outbound logistics, and marketing and sales (Burlton, 2001).

Support processes, on the other hand, “do not add value, but are necessary to assure that the core processes continue to function” (Harmon, 2007, p.86), and support processes include human resources development, development of technology, procurement and overall infrastructure.

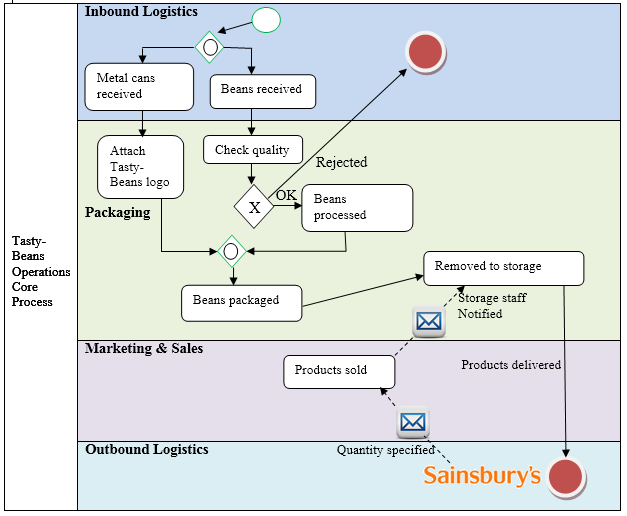

BPNM stands for Business Processes Modelling Notation and it assists with finding and utilising possibilities for increasing the levels of effectiveness of various business processes. Mapping of Tasty-Beans Co. canned been manufacturing operations provided below only comprise core processes:

Analysis of Sub-Section Process: Packaging

Illustration of Mapping of Tasty-Beans Co. canned been manufacturing operations provided above captures main activities within core elements of operations in general manner. Each of lanes within the pool such as inbound logistics, packaging, marketing and sales and outbound logistics can be further expanded in a lower level map in order to gain more detailed information about improvement prospects.

For example, the following figure contains lower level process analysis of Tasty-Beans Co. operations, focusing on packaging element of core operations:

Four characteristics of operations known as ‘4Vs’ have been specified as volume, variety, variation, and visibility (Slack et al., 2007). This framework can be applied in relation to Tasty-Beans business operations in the following manner:

Volume

According to the level of volume and extend of variety manufacturing can be divided into project, jobbing, batch, mass, and continuous categories. Large volumes of Tasty-Beans products are produced on a daily basis to be delivered to Sainsbury’s distribution centres, therefore operations of Tasty-Beans Co. can be classified as mass manufacturing.

Accordingly, Tasty-Beans Co. offer limited product variety as discussed below, and packaging process do not require advanced human resources skills. Moreover, establishment of mass production requires substantial amount of financial investments (Piperopoulos, 2013), and this fact creates certain barrier for other firms to compete with , Tasty-Beans Co.

Variety

Tasty-Beans Co. offers three varieties of canned beans: Tasty Beans Great Northerns, Tasty-Beans Kidney, Tasty-Beans Canellini and Tasty-Beans Mixed. Lack of variety of products offered by Tasty-Beans Co. enable the use of mass manufacturing in packaging practices. However, on the negative side lack of variety within brand offerings may cause emergence of new competitors (Baron and Shane, 2008).

Variation

Variation relates to the extent of demand for products and services. Tasty-Beans Co. operations have low variation, as the level of demand for its products can be specified as fairly stable. This position allows the company to decrease the unit cost, because the levels of use of resources are usually predicted with an acceptable range of accuracy, and employee overtime payments are avoided (Payne, 2012).

Visibility

Tasty-Beans Co. products are associated with low visibility, and therefore most of the business processes are highly standardised. Moreover, the majority of employees do note communicate with customers in a direct manner, and a big segment of employees are engaged in manual operations due to the high level of standardisation of business processes.

IGOE abbreviation stands for Input, Guide, Output and Enabler and these represent basic components of business processes.

Input relates raw materials that are subjected to transformation. For Tasty-Beans products in particular inputs involve various types of beans and metals to be transformed to packaging cans.

Guides relate to manners, frequency and objectives of transformations. Tasty-Beans Co. packaging and related processes are regulated by a formal document entitled ‘Packaging Procedure Manual’. Moreover, Tasty-Beans Co. organisational culture has been developed in a way that focus on quality and assistance to each-other during operations are highly valued.

Outputs produced by Tasty-Beans Co. packaging operations are four types of canned beans – Tasty Beans Great Northerns, Tasty-Beans Kidney, Tasty-Beans Canellini and Tasty-Beans Mixed.

Enablers are tangible and intangible resources that are used by Tasty-Beans Co. to conduct its packaging operations. Resources used to conduct Tasty-Beans Co. packaging operations include packaging equipment, facilities, contributions of members of staff, systems etc.

Conclusions

The impact of operations management on the achievement of organisational objectives is greater than ever before. Specifically, the main organisational objective in private sector relates to profit maximisation and effective operations management can increase the levels of operational profits through increasing the levels of effectiveness of individual core and support elements of the process.

Illustrations of mapping of Tasty-Beans Co. canned been manufacturing operations and lower level process analysis of packaging provided in this report can assist Tasty-Beans Co. management in terms of finding and using opportunities to reduce operational costs and increase the levels of effectiveness of individual processes.

Moreover, analyses conducted with the application of Four V’s’ and IGOE frameworks can assist with achieving this objective in an effective manner.

References11

Baron, R.A. & Shane, S.A. (2008) “Entrepreneurship: A Process Perspective” Cengage Learning

Burlton, R. (2001) “BPM: Profiting From Process” Sams Publishing

Draheim, D. (2010) “Business Process Technology: A Unified View on Business Processes, Workflows and Enterprise Applications” Springer Group

Harmon, P. (2007) “Business Process Change” 2nd edition, Morgan Kaufmann

Payne, T. (2012) “Facilities Management: A Strategy for Success” M-Y Distribution

Piperopoulos, P.G. (2013) “Entrepreneurship, Innovation and Business Clusters” Gower Publishing Ltd.

Slack, N., Chambers, S. & Johnson, R. (2007) “Operations Management” 6th edition, Prentice Hall