Toyota Value Chain Analysis

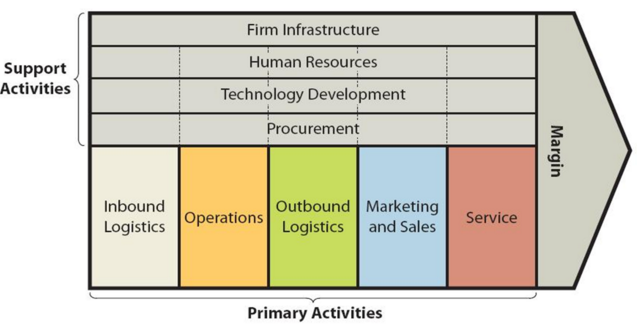

Value chain analysis is an analytical framework that assists in identifying business activities that can create value and competitive advantage to the business. Figure 1 below illustrates the essence of value chain analysis. You can learn the theory of value chain analysis here.

Inbound logistics

Inbound logistics for Toyota comprises two separate operations. The first is the operation “that transports parts from local suppliers to the local plants; the second is a separate operation, global inbound logistics, to transport parts from Japan to the North American and European plant”.[1]

Localization of production is one of the core strategies pursued by Toyota and accordingly, 75.4% and 76.3% of non-domestic sales were produced outside of Japan for the calendar years of 2012 and 2013 respectively.[2] Thanks to localization of production, Toyota is able to achieve better match of local currency revenues with local currency expenses. Moreover, Toyota has developed and perfected Just-In-Time (JIT) system of manufacturing that eliminates the need for inventory and inventory management, thus saving considerable costs. To summarize, inbound logistics is a primary activity that creates an immense value for Toyota due to the localization of production and efficiency application of JIT supply chain system.

Operations

In 2013 Toyota automotive operations were reorganized into the following four units:

- The Lexus International. The business unit is assigned the role of the global head office for Lexus brand development, sales, marketing and advertising.

- Toyota No.1. This unit is in charge of North America, Europe, and Japan.

- Toyota No.2 unit caters for emerging markets of China, Asia & the Middle East, East Asia & Oceania; Africa, Latin America & the Caribbean

- Unit Cellar. This unit deals with unit-related technological development, manufacturing technology development and production

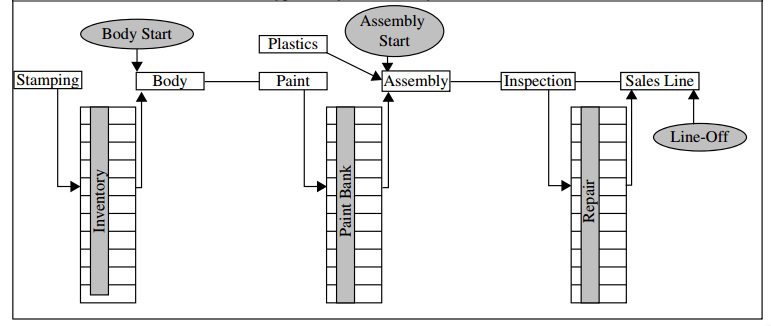

Toyota promotes a spirit of monozukuri i.e. conscientious manufacturing throughout its operations and lean manufacturing represents one of the core sources of Toyota competitive advantage. As it is illustrated in Figure 2 below, a typical Toyota assembly plant comprises.

Figure 2 Typical Toyota assembly plant flow[3]

Outbound logistics

Toyota has approximately 170 distributors and 8,900 dealers outside of Japan[4]. The company uses “common carriers, railroads and truck “car haulers,” to transport its vehicles from the assembly plants to the dealers”[5]. Toyota uses different distribution strategies in US, Europe and Japan.[6]

Distribution practices used in US can be further divided into three categories:

- Distribution of vehicles produced in North America. Once out of the plant, vehicles are transported into the marshalling yard, where they are prepared for the shipment. This is followed by shipment of vehicles into dealership offices via train and truck.

- Distribution of vehicles produced overseas. Large vessels are used to transport vehicles produced in Japan to ports in North America and to be further transported to dealerships. The delivery times varies between three to five weeks and vehicles are delivered to ports located close to dealers. Therefore, the most popular ports used are the ones located in cities such as Portland, Oregon; Long Beach, California; Houston, Texas; Jacksonville, Florida; and Newark, New Jersey.

- Scion model of distribution. This model relates to the distribution of vehicles produced in Japan in the US, however there are some differences between the Scion model and the previous model discussed above. In Scion model vehicles arrive from Japan with only basic equipment installed to be further customized in the US according to required specifications by dealers.

European distribution pattern of Toyota vehicles is different from US distribution due to the location of dealers in urban areas and hence, the absence of room for vehicle stock. After the production vehicles are taken to the marshalling yard to prepare them for the shipment. Then, vehicles are taken by truck to a consolidation place known as ‘hub’. Generally, each European country has one ‘hub’. At the same time, there are several hub in large counties and a number of smaller countries do share one hub. The hub performs the role of warehouse and additional accessories may be installed at the hub as requested by dealers according to customer order.

Distribution of vehicles in Japan is similar to vehicle distribution in Europe in a way that dealership offices have a small storage capacity. In Japan, each Toyota dealership office has a consolidation centre, which is assigned the role of storage, until a vehicle has been sold by the dealership office.

Marketing and sales practices at Toyota emphasize innovativeness and efficiency of the brand, as well as, integration of brand with the best practices of Japanese ways of doing things. Toyota marketing strategy utilizes a combination of print and media advertising, sales promotion, events and experiences, public relations and direct marketing techniques with a particular focus on television advertising.

Service. Toyota operates according to the principle of ‘The Customer Always Comes First’ as declared in “The Toyoda Precepts” in 1935. This principle is reflected in all business processes and procedures of the company. Figure 3 below illustrates a schematic diagram of dealing and obtaining the customer feedback in the case of Toyota Japan.

Figure 3 Schematic diagram of Toyota customer responses[7]

Toyota Motor Corporation Report contains more detailed discussion of Toyota value chain analysis covering analysis of support activities. The report also comprises an application of SWOT, PESTEL and Porter’s Five Forces Analyses on Toyota, along with analysis of Toyota’s marketing strategy and company’s approach towards Corporate Social Responsibility (CSR).

[1] Iyer, A., Seshadri, S. & Vasher, R. (2009). “Toyota Supply Chain Management: A Strategic Approach to the Principles of Toyota’s Renowned System” McGraw-Hill Professional

[2] Iyer, A., Seshadri, S. & Vasher, R. (2009). “Toyota Supply Chain Management: A Strategic Approach to the Principles of Toyota’s Renowned System” McGraw-Hill Professional, p.103

[3] Annual Report (2014) Toyota Motor Corporation

[4] Toyota Sustainability Report (2015)

[5] Toyota Management System (2009) Available at: http://www.ineak.com/toyota-logistics-operation/

[6] Comprehensive Overview of Supply Chain (2009) Available at: http://www.ineak.com/comprehensive-overview-of-supply-chain/

[7] Toyota Motor Corporation (2016). Available at: https://www.toyota.co.jp/en/environmental_rep/03/kakawari.html